All about paraglider fabrics

Paraglider fabric is a critical component that influences a wing's performance, durability, and safety. Manufacturers utilise various materials and coatings to achieve the desired balance between weight, strength, and resistance to environmental factors.

Porcher Sport's Skytex

Porcher Sport's Skytex range is renowned for its durability and performance. Skytex 27, for instance, is an ultralight fabric weighing 27 grams per square meter, favoured in hike-and-fly wings for its minimal weight and pack size. Despite its lightness, it offers reasonable durability with proper care. Skytex 38 and 40 are heavier variants, providing increased durability and UV resistance, suitable for standard and tandem wings. The E68A variant, used in models like the Ozone Geo II, is considered a gold standard for durable, lightweight material.

Dominico Textile's DOKDO

Dominico Textile's DOKDO fabrics are widely used in the paragliding industry, known for their balance between weight and durability. The DOKDO 20D variant is lightweight, suitable for performance wings, while the 30D offers enhanced durability for intermediate and beginner gliders. DOKDO fabrics are coated to improve UV resistance and longevity, making them a reliable choice for various flying conditions.

MJ29 MF by Gin Gliders and MJ Tex

MJ29 MF is a lightweight paraglider fabric developed collaboratively by Gin Gliders and textile manufacturer MJ Tex. It employs a custom 15-denier yarn with a triple ripstop pattern, enhancing strength while maintaining lightness. The fabric undergoes a unique "Quattro" coating process, involving double coating applied twice over two days, which improves air porosity and durability. This meticulous process results in a softer hand feel, reducing micro-cracking and enhancing longevity. MJ29 MF is exclusive to Gin Gliders and is featured in models like the Gin Avid, designed to withstand harsher environments.

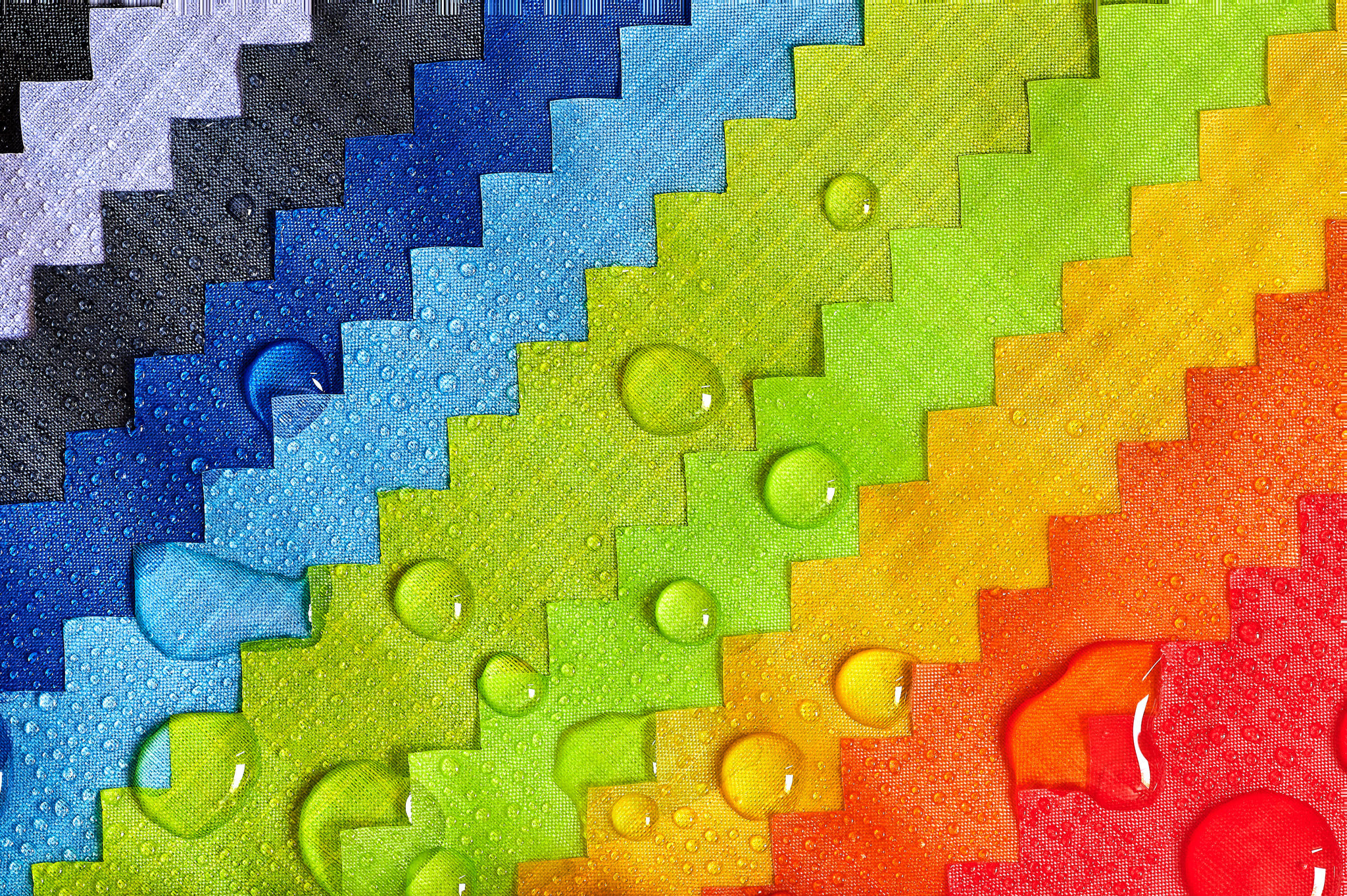

Durability and UV Resistance

Durability in paraglider fabrics depends on factors like denier (fiber thickness), ripstop patterns, and coating quality. Higher-denier fabrics, such as 30D or 40D, generally offer increased durability and UV resistance but come with added weight. Coatings like polyurethane (PU) or silicone enhance UV radiation and moisture resistance, extending the fabric's lifespan. For instance, the NOVA DOUBLESKIN features lightweight fabrics that shine due to minimal pack size and high UV resistance.

Weight Considerations

Weight is a crucial factor in paraglider performance. Ultralight fabrics (e.g., 20D or 27g/m²) reduce overall wing weight, enhancing portability and handling, especially in hike-and-fly scenarios. However, lighter fabrics may compromise durability and require careful handling. Heavier fabrics (e.g., 30D or 40D) provide robustness and longevity, suitable for training wings or frequent flyers.

Cost and Availability

Paraglider fabric costs vary based on material quality, coating processes, and brand reputation. High-performance fabrics with advanced coatings, like MJ29 MF, Skytex 27 etc. tend to be more expensive due to their specialised manufacturing processes. Some times availability is limited to specific paraglider manufacturers or models, as some fabrics are exclusive collaborations. For example, MJ29 MF is exclusive to Gin Gliders.

Conclusion

Selecting the appropriate paraglider fabric involves balancing weight, durability, UV resistance, and cost to match your flying style and conditions. Understanding the characteristics of different fabrics and their applications can guide you in making an informed decision, ensuring safety and optimal performance in the skies.

Safe flights and happy glides!